All our 90 degree tippers are built to customer requirements as no two loads are ever quite the same

We specialise in hydraulically powered 90° tipper systems handling 500 kgs to 15000kgs and build machines purely to order according to the size and weight of your loads and your methods of handling.

The 90° tipper’s most common applications involve tipping paper reels through 90° for processing and turning steel coils to suit delivery or storage requirements.

All 90° tipper machines are painted with two coats of zinc primer and a 2 pack epoxy acrylic top coat as standard.

There are three styles around which we base our customised designs

Type ’1′

Loads at a raised Height and tips to ground level ( or vice versa ) so loads can be rolled on and off.

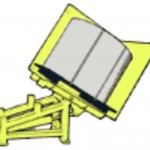

Type ’2′

Loading and discharging at a raised height, it is ideal for very heavy loads.

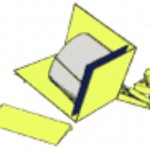

Type ’3′

Tips to ground level on one side and almost to the floor on the other but the turning system ensures there is no need for a pit.

Image Gallery

More on the 90° Tipper Pallet Inverter

Customers who have seen the 180 degree inverters in operation have recognised a potential solution to a more simple problem of tipping paper and steel coils through 90 degrees.

Rather than employ the rack and pinion system from the 180 degree models they are powered by one or two hydraulic rams pushing on a cam mounting at the corner of the two tables and pivoting on twin bushes.

All our 90 degree tippers are built to customer requirements as no two loads are ever quite the same. However, there are three basic design principles that can be adapted to virtually all circumstances.