![]()

Assist warehouse case pickers to combine and separate palletised products

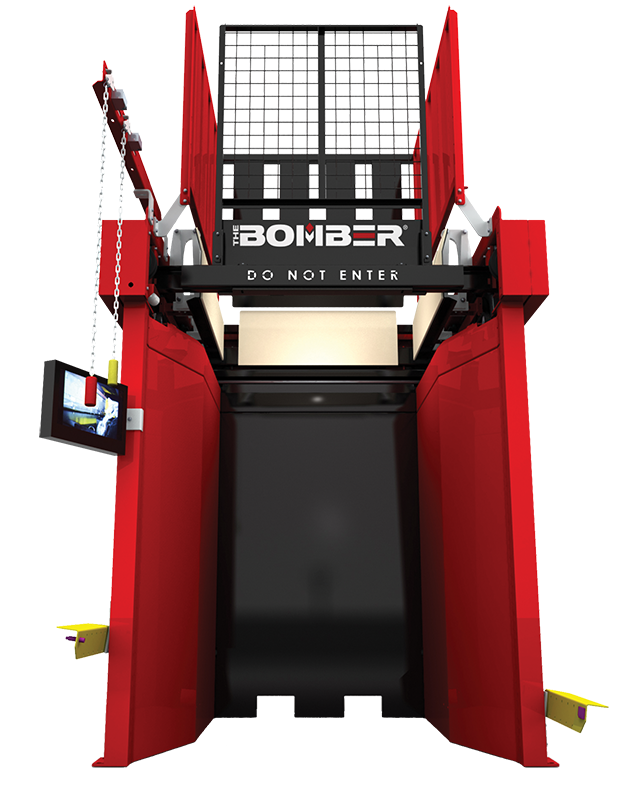

The Q-Tek Bomber is a 2.1m x 2.1m stationary machine with four case clamps.

This unique “Case Stacker” is used to assist warehouse case pickers to combine and separate palletised products.

The Q-Tek Bomber’s rubber case clamps are gentle, air-operated, and easily support 1 layer or an entire pallet.

THROUGH-PUT CAPACITY:

Pallet Splitting: 60 seconds, Additional Layer Picking: 30 seconds

Bottles: 1,920 Cases/Man Hour, Cans: 2,352 Cases/Man Hour

RETURN ON INVESTMENT:

Clients Experience a 3 – 18 Month Payback, Reported Annual Savings: $40K – $200K

REDUCED INJURIES & HANDLING DAMAGE COSTS

Minimizes Hand Stacking Injuries, Eliminates Damage From Hand Picking

Helps Lower Insurance Premiums

COMPLETELY FLEXIBLE PALLET ACCOMMODATION:

770mm x 920mm up to 1100mm x 1320mm Footprint

Changeover in Just 20 Seconds

NO DEDICATED EQUIPMENT REQUIRED:

Use Current Forklift With 2m Lift Capacity

MINIMAL SPACE REQUIRED:

3.7 sq m Footprint x 3.9m Height Clearance, Install or Relocate in Under 2 Hours

APPLICATIONS:

Building Starter Pallets, Pallet Splits, Damaged Product Replacement, Quick Pallet Exchange, Upstack or Destack Product Layers, Club Store Pallet Builds

Superior Pallet Splitting and Layer Picking.

Operation Sequence

- Drive product into the cavity with any forklift

- Raise product up to the desired height

- Pull chain, activating the clamps

- Product between the case clamps and above are held by the clamps

- Drop down and return with another pallet or product

- Pull the chain again

- Supported layers are released on top of the new pallet or product